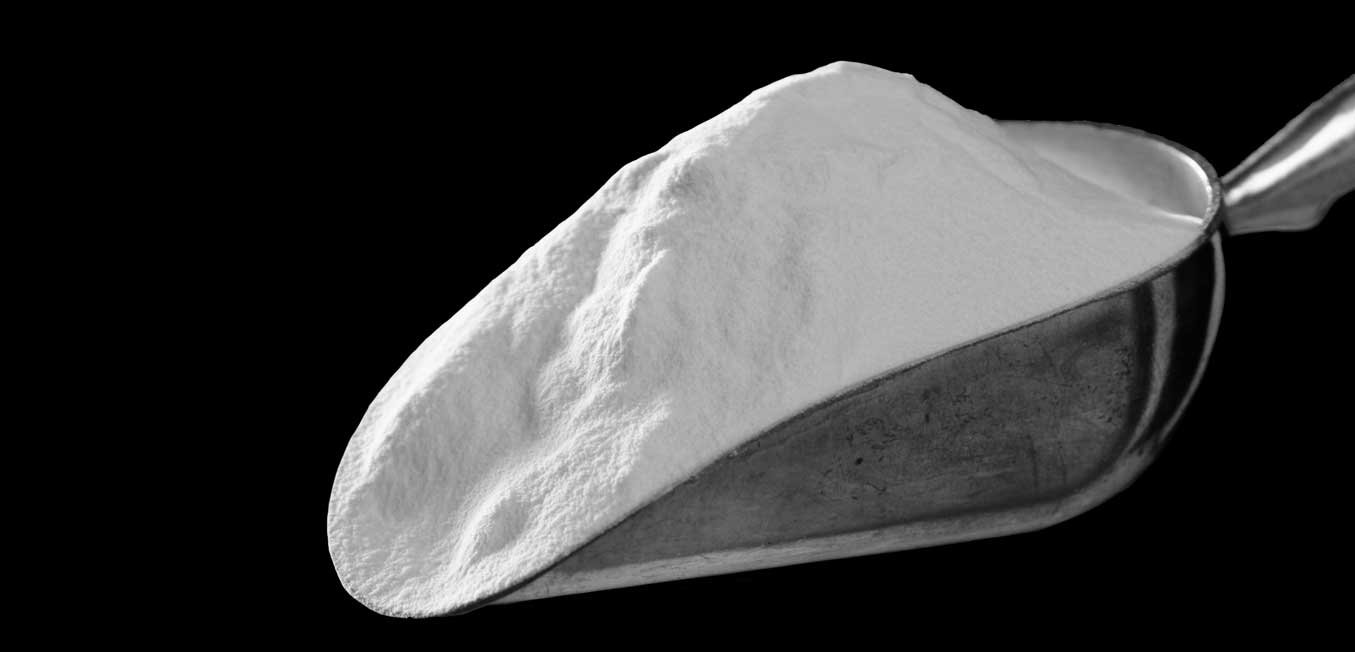

Potato Granules: dehydrated whole potato cells

Dehydrated Potato Granules

The first manufacturing of potato granules was in 1952 by R.T. French in Shelley, ID. The product and process are quite different from potato flakes/flour in that the product is air dried versus drum dried, which preserves the integrity of the potato cell. The product resembles granular flour in appearance but has less free-flowing starch due to the gentle drying process. Granules are highly absorbent with relatively low viscosity, have less gelling capacity and hold water with little cohesion.

Uses

Granules are popular in foodservice applications for reconstituting into mashed potatoes in part due to their economy and consistent quality. Their simplicity of use makes granules more user-friendly than potato flakes in their preparation which is one reason they are widely used in mass feeding operations such as hospitals, schools, nursing homes and similar institutions.

Granules are suitable for use in many applications both for foodservice products and as ingredients in other food products. For foodservice, granules serve as the main source of mashed potato products. Products range from unseasoned to fully seasoned and can be a mix, or an agglomerated product which infuses the various seasonings. As an ingredient for other food products, granules are used in sheeted dough processes, extruded processes, fried, baked, and pelleted snack products like chips, sticks and crackers; flavorings and thickeners; and breadings, soups, and frozen dinners.

Granule Uses

Binder

The free starch present in Dehydrated Potato Granules can be used as a binder in meats and other products.

Breading

Dehydrated Potato Granules can be used alone or combined with flour, cornmeal and/or crushed corn flakes to create breading for fish, meat, or vegetables. For fried foods, the use of U.S. dehydrated potatoes lends a crispy texture that is difficult to attain with other breading.

Enhancer (Color)

In baked goods such as breads, rolls and cakes, the addition of dehydrated potatoes can enhance crust color, producing a thicker, darker crust.

Enhancer (Flavor)

Dehydrated Potato Granules can be used to produce potato-flavored snacks and baked goods. When used in bakery products they impart a unique potato flavor and soft mouthfeel to the product. Dehydrated potatoes will produce a unique potato flavor. The potato flavors are mild enough that they complement other flavors in snack foods.

Enhancer (Texture)

Dehydrated Potatoes Granules will produce products with unique soft eating characteristics (mouthfeel). The addition of potato granules to recipes creates a moister texture for cakes, doughnuts, breads, rolls and pastry items. Added to snacks, they aid in creating a light, crisp texture.

Extender

Dehydrated Potato Granules can be added to burgers or patties before cooking, thus requiring less meat per burger.

Gluten-Free Formulation

Dehydrated Potato Granules can replace gluten-containing ingredients in a range of applications where gluten-free demand runs high.

Shelf Life Extender

At low inclusion levels, Dehydrated Potato Granules serves as an anti-staling or crumb-softening agent in bakery applications, with no alteration of the taste profile. Because of their moisture retention abilities, potato products slow the drying effect associated with staling. Dehydrated potatoes can be used to replace chemical additives used for anti-staling purposes, giving products a clean-label by replacing chemical additives with the natural dehydrated potato ingredient.

Thickening Agent

Dehydrated Potato Granules can be added to broths, gravies, sauces, and stews to thicken. Granules are much more forgiving than flour, which may create lumps.

Uniformity

Dehydrated Potato Granules can be used in salty snacks such as fabricated chips to create a more uniform shape.

Yield Increase

The weight of the added Dehydrate Potatoes Granules and the resulting absorption increase for hydration may increase dough yield for baked goods.

Additives / Ingredients

Mono & Diglycerides

This is an emulsifier which reduces the stickiness of the product by binding up some of the free starch. It is used both as a processing aid – helping the dehydrated potato peel off the drum, and it also assists in improving the texture of the rehydrated product.

Sodium Acid Pyrophosphate

SAPP binds naturally occurring metallic ions in the potatoes, acting as a chelating agent, and preventing those metals from oxidating. This helps maintain the color of the product.

Sodium Bisulfite

This is used to help protect the natural color of the product from non-enzymatic browning (e.g., Maillard Reaction) as it reduces the effect of chemical reaction in the product between the amino acids and reducing sugars.

Citric Acid

This additive also helps maintain the natural color of the product by biding up metallic ions

Color, Spices & Flavors

Some of our value-added product offerings will contain flavors (e.g., butter, salt, etc.) and colors (e.g., turmeric). These typically will be foodservice or retail products.

Let’s Chat

We are here to answer your questions, and help you with your ideas.

Production Process

Shelf Life

Average of 12 months from manufacturing date when stored in cool, dry conditions (<30ºC and <65% humidity) in the original packaging. Please refer to your particular product’s specification sheet as some ingredients and/or packaging may affect that product’s shelf life.